Manufacturing Execution — MES

- Key Features

- Gantt Scheduling

- Routing

- Real-time Labor & Material Reporting

- Production Floor HUDs (Heads-up Displays)

- Work Order & Work Breakdown Structures

- BIM & Document Viewers

- Document Management

More Solutions

Manufacturing Software for Modular Offsite Manufacturers

As a manufacturer, you take raw materials and craft them together to form a finished good. It should come as no surprise that tracking materials with precision is key. Moducore gives you the tools to effortlessly be precise.

When the Bill of Materials becomes the vehicle in which material can not only be requisitioned for purchase, but also how material is requested from the warehouse — creating and maintaining an accurate BoM becomes a lot easier. A BoM that saves dollars instead of simply costing them.

Change Management

Orchestrate Change Management from a project or facility point-of-view and optimize maintenace and minimize rework.

Learn moreMobile Viewing

Take 3D models with you to the shop floor, into the field or around the office with an integrated Autodesk Viewer.

Learn moreVirtual Twin

Turn your 3D Models into Virtual Twins with smart device connectivity, asset tracking, embedded O&M manuals & more.

Learn moreDetailed Activity History

How long would it take to calculate just one of these metrics today on a per-project basis?

Understand where you started, where you are at, and forecast where you are going earlier with Moducore — make decisions based on data long before the project ever becomes at risk.

Our integrated Design, Procurement, Change Management, Materials and Scheduling tools give project managers a more accurate financial picture based on data throughout the entire project. Sitting at the core of each your manufacturing projects, Moducore can serve project managers with hard-to-get construction & manufacturing project management metrics at the click of a button.

Gantt Scheduler

While you are quantifying materials on the BoM Moducore is scheduling them

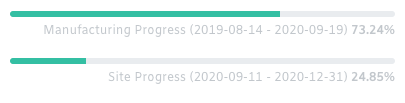

The built-in Gantt Scheduler tool talks directly with your Inventory and Procurement systems, and allows you to view Manufacturing and Site schedules independently, or in split-view.

Batches, Jobs and Units

Manufacture highly custom or repeatable projects with confidence from the very beginning

Our proprietary Bill of Materials system presents you with a simple, yet intuitive interface all while intelligently managing independent Bills of Material for every single unit — now that's precision.

- Integrated labor tracking for unit-level reporting

- Suspend or Remove single units mid-production to remove material requirements from resource planners

- Insert Units into manufacturing mid-stream without disruption or add entirely new jobs

- Integrated opt-in/out text message, email and system notifications when changes occur

Manufacturing and Jobsite Reporting

Gain visibility into each side of the offsite manufacturing project — together, or separately

Track individual manufactured units independently at the plant, and at the jobsite.

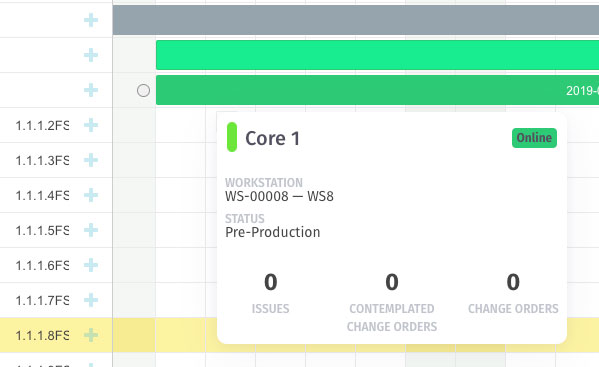

- Track Submittals, RFIs, Issues, Contemplated Change Orders and Change Orders — all with varying workflows to ensure the control of information is accurate, and timely.

- Integrated Submittal process to ensure only approved drawings make it down to the production floor.